Process Automation

Our process automation capabilities cover a wide range of advanced manufacturing technologies, including precision dispensing, lamination and pressure-controlled assembly, screw fastening, metal laser welding, and other customized production automation solutions designed for high-precision manufacturing environments. We are committed to the research and development of intelligent automated assembly technologies, with in-house integration of 2D and 3D vision-based dynamic trajectory guidance and control systems. Through continuous technological innovation and refinement, we deliver high-value engineering solutions that enhance accuracy, consistency, and scalability for our customers in the precision manufacturing industry.

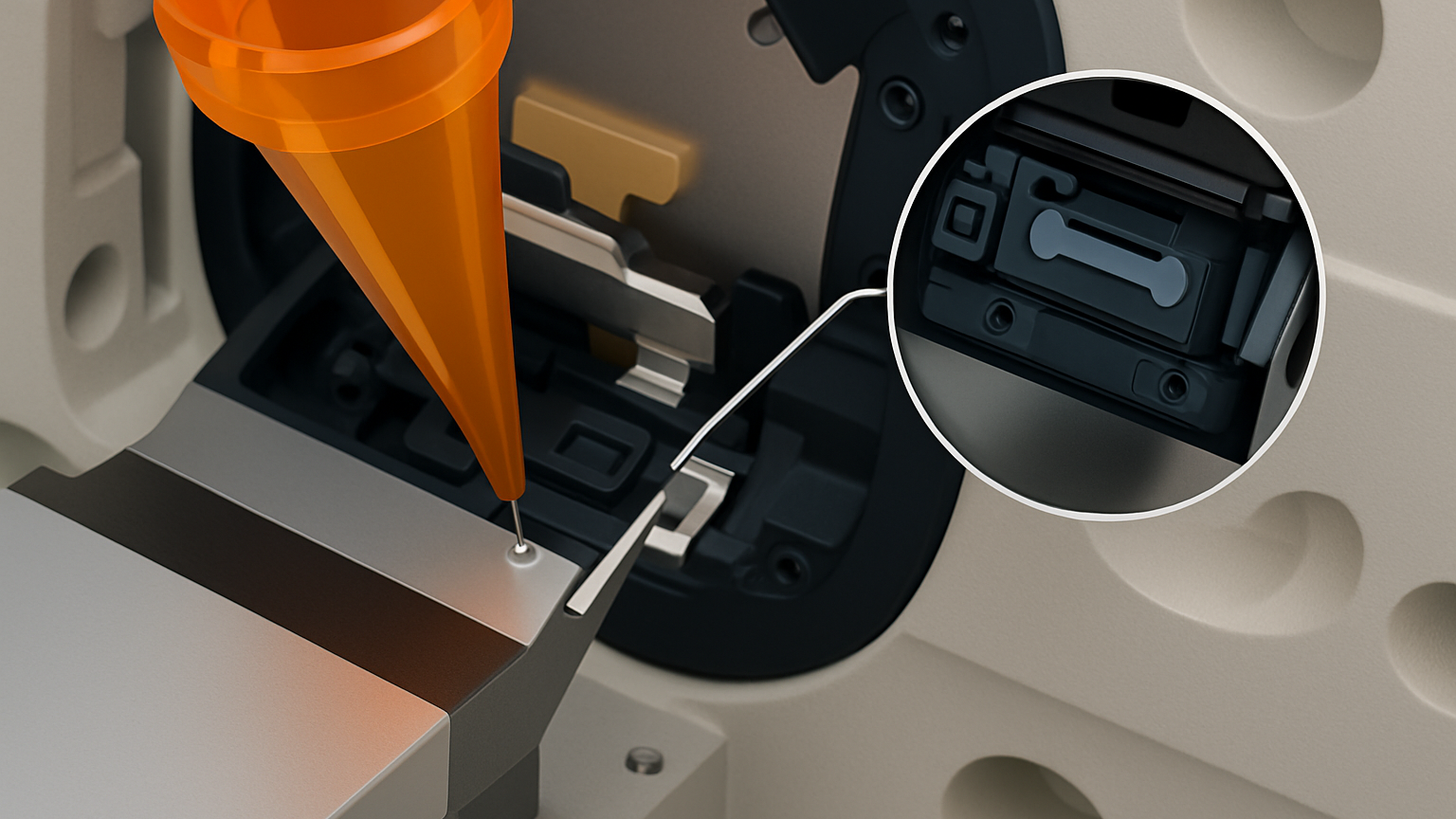

Precision Dispensing

Sub-10 mg dispensing accuracy supporting multi-material LDAs, including one-component, two-component, hot-melt, and UV-curable adhesives with controlled gap-sealing performance.

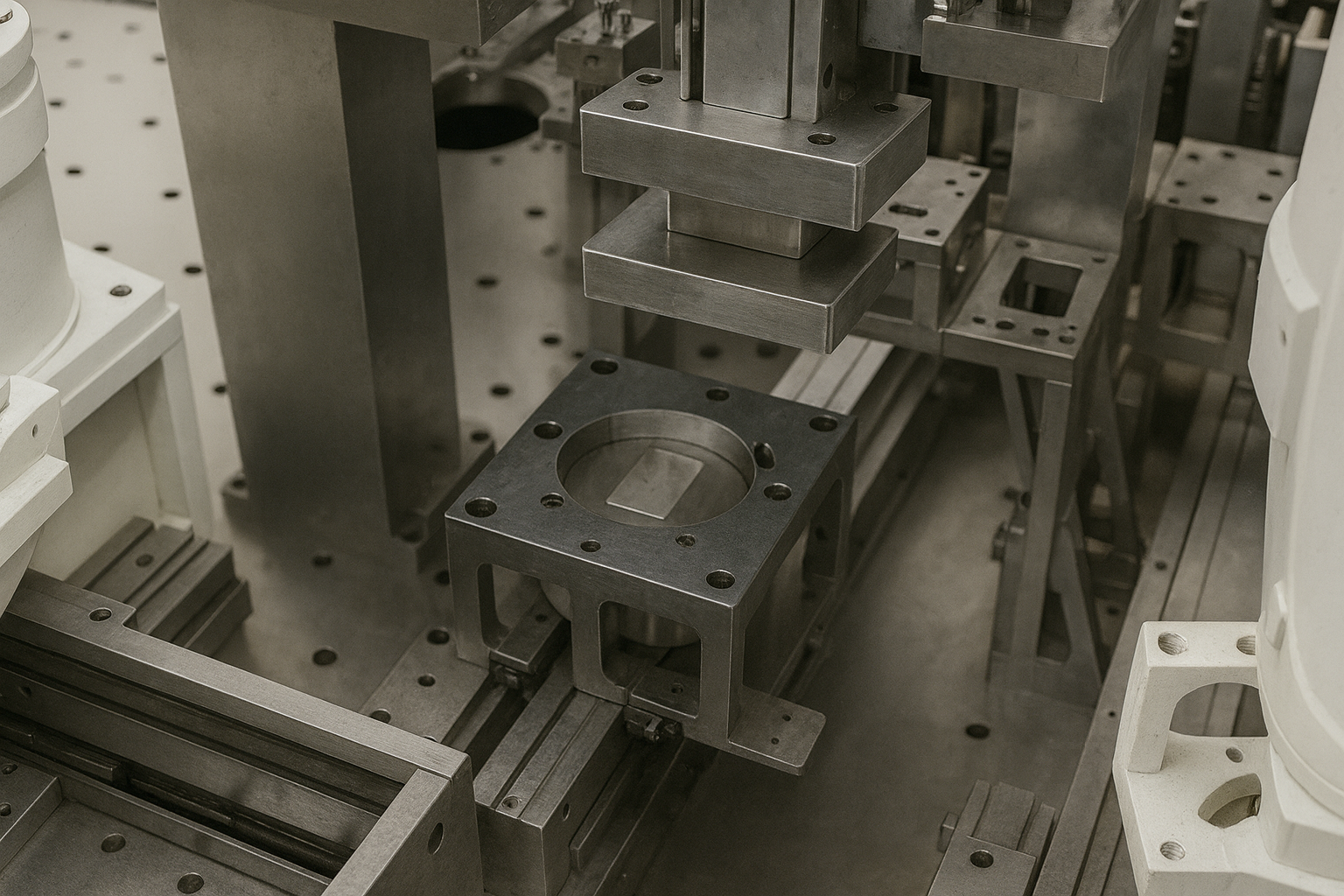

Lamination / PSA Bonding

Specialized in PSA and OCA film lamination processes, with a strong focus on high-precision applications for critical components such as optical assemblies and battery modules, ensuring consistent bonding quality and process stability.

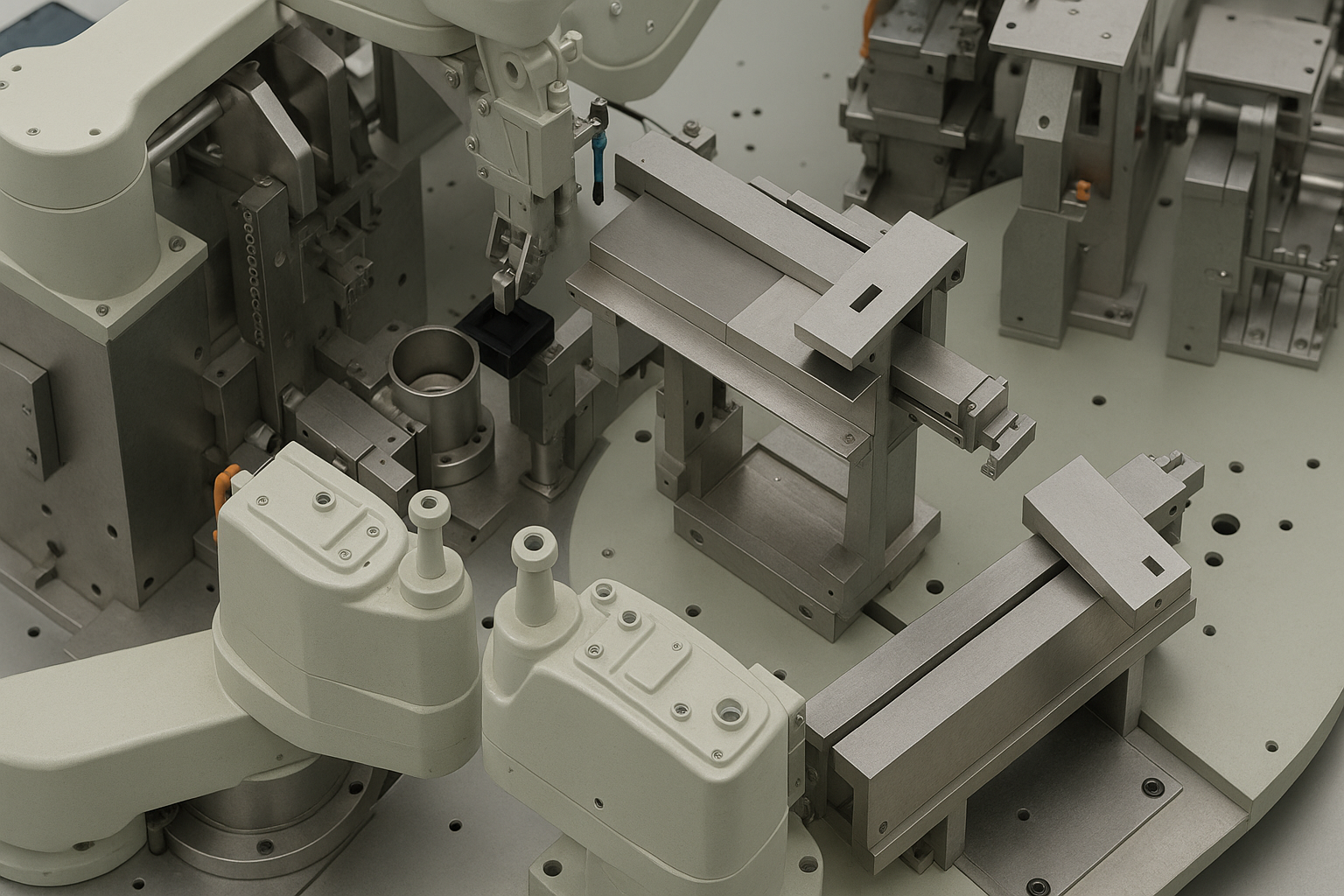

Screw Fastening

Automated, vision-guided screw fastening designed for high-precision wearable assemblies, supporting micro-fasteners down to M0.8, with controlled torque and high repeatability to ensure assembly consistency and reliability.

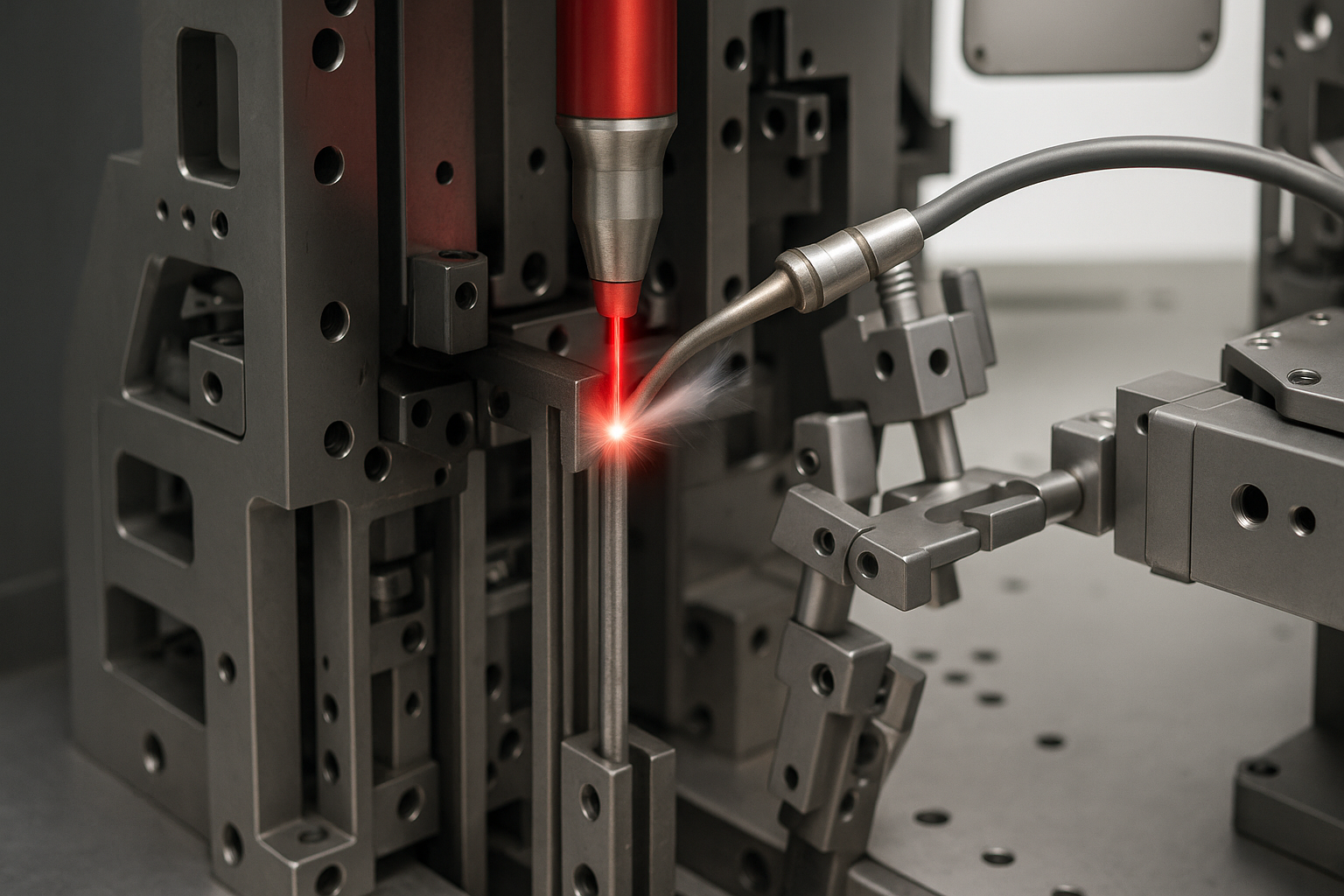

Laser Welding

Automated laser weld bonding solutions for metal-to-metal joining, primarily applied in enclosure manufacturing automation, delivering high precision, consistent weld quality, and reliable structural integrity.

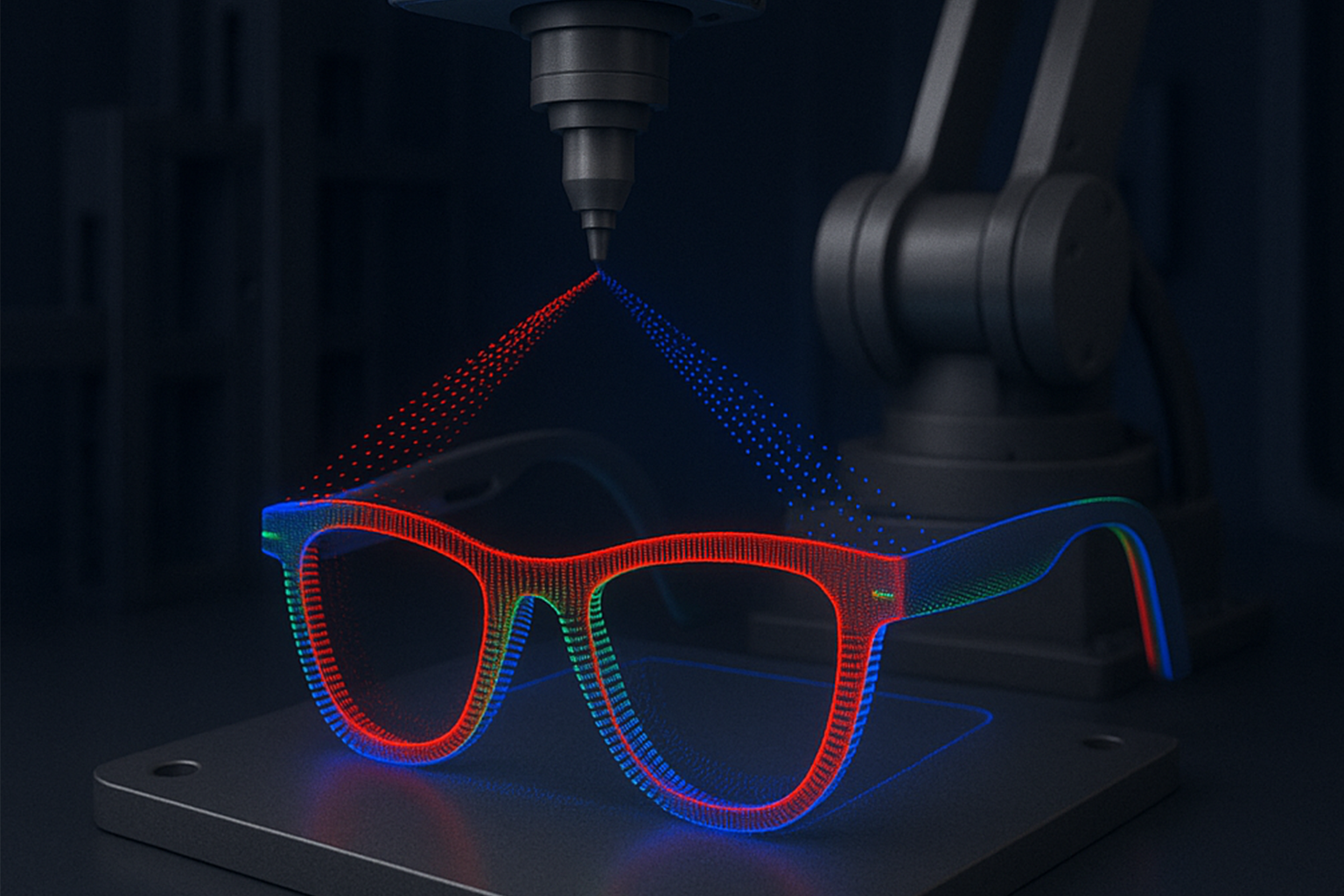

3D Dynamic System

Our fully automated 3D Dynamic System leverages advanced 3D vision to generate high-density point cloud data and extract precise motion paths for robotic guidance. This system enables true vision-driven robotics in a three-dimensional spatial environment, allowing robots to dynamically adapt to part geometry and positional variation.

The system supports a wide range of manufacturing and assembly processes, including LDA dispensing, gap filling, screw fastening, laser cutting, 3D surface painting, and pick-and-place operations with orientation and rotation correction. It is also capable of handling translucent and transparent materials, ensuring robust performance across diverse applications.